Remember that time you tried to print a vital document at the last minute, only to discover your printer was out of ink? Frustrating, right? Or when you wished you had a better understanding of how the latest printing technologies work? Well, this post explores the landscape of the print industry, specifically focusing on printing united 2025. We’ll explore innovations, key players, and the shifts driving the evolution of this vital industry. By the time you’re done reading, you’ll have a clear picture of what the future holds for printing united 2025 and how it impacts businesses and consumers. This exploration will enhance your knowledge and equip you with the insights to stay ahead in this dynamic field.

Key Takeaways

- Explore the latest innovations shaping the print industry.

- Understand the major trends impacting printing united 2025.

- Discover the key players driving change in the print sector.

- Learn about the impact of digital technologies on printing.

- Gain insights into the future of print and its potential.

- Examine the evolution of sustainable practices in printing.

Overview of the Printing Industry

The print sector is a vast and diverse area, encompassing everything from simple home printers to massive commercial operations. It’s a field that has continuously changed, adapting to new technologies and customer requirements. The industry is responsible for creating a wide variety of materials, including books, newspapers, packaging, marketing materials, and much more. This industry provides essential services for both businesses and consumers. Currently, there is a global push towards more environmentally friendly methods and integrating digital technologies to improve efficiency and reduce waste. The industry is looking at methods to enhance automation, streamline workflows, and ensure high-quality outputs that meet the growing demands of the market.

Historical Context and Evolution

The history of printing is long and interesting, beginning with the invention of the printing press by Johannes Gutenberg in the 15th century. This innovation allowed for the rapid reproduction of texts, which revolutionized information dissemination. Over the centuries, printing technologies improved through offset printing, which significantly enhanced print quality and speed. The transition to digital printing in the late 20th century further changed the industry. Today, we’re seeing continued advancements, including advancements in ink and materials, along with a focus on sustainable practices.

- The Gutenberg press marked a revolutionary moment, enabling mass production of books and documents.

- Offset printing offered a more efficient and higher-quality print output.

- Digital printing introduced new capabilities, like variable data printing, which allowed for customization.

- The current era is characterized by a blend of digital and analog technologies and a focus on sustainability.

Key Players and Market Dynamics

The print industry includes a diverse set of companies, from equipment manufacturers to print service providers and material suppliers. Large corporations like Canon, HP, and Xerox are major manufacturers of printing equipment, while companies like RR Donnelley provide large-scale print services. The market dynamics are shaped by variables such as technology developments, economic trends, and shifts in consumer behavior. Competition is intense, forcing companies to innovate and provide value-added services. The market’s success depends on the ability to anticipate and respond to changing market demands, embracing digital tools, and providing cost-effective and environmentally friendly solutions.

- Canon, HP, and Xerox are among the leading producers of printing equipment.

- RR Donnelley provides comprehensive print service solutions for diverse requirements.

- Market dynamics are influenced by technology advances, economic patterns, and consumer preferences.

- Success depends on innovation, customer service, and incorporating digital tools.

Exploring the Trends in Printing United 2025

Printing united 2025 is expected to be defined by a series of significant trends, including the increasing role of digital technology, a greater focus on sustainability, and improved automation across production processes. These trends are poised to change how print businesses operate. The industry is also seeing a rise in specialized printing solutions, catering to the specific needs of diverse sectors, such as packaging, textile printing, and 3D printing. Understanding these trends is key to knowing the future of the print industry and preparing for upcoming changes.

Digital Transformation and Its Impact

Digital technologies are causing a significant change in the print sector, enhancing efficiency and creating new possibilities. The use of digital printing technologies, cloud-based workflow solutions, and data analytics tools is improving print operations. Digital printing offers flexibility and speed, making it perfect for custom projects and shorter print runs. Cloud-based solutions allow for remote access, collaboration, and simplified print management. Data analysis helps print businesses improve their operations and anticipate client needs. This shift is helping businesses reduce expenses, improve customer service, and streamline their processes.

- Digital printing enables on-demand printing and personalization, improving flexibility.

- Cloud solutions offer streamlined workflows, promoting access and collaboration.

- Data analytics enhances operational efficiency and customer insights.

- Digital transformation is helping print businesses to reduce costs and boost customer service.

Sustainability and Eco-Friendly Practices

Sustainability is becoming a major focus within the printing industry, with increasing demand for eco-friendly practices and materials. Businesses are embracing sustainable methods to decrease their impact on the environment. This includes using recycled paper, eco-friendly inks, and energy-efficient equipment. Many print businesses are getting certifications to show their commitment to sustainability. Businesses are also working to reduce waste, optimize resource use, and enhance recycling programs. This move towards sustainability not only benefits the environment but also aligns with the growing demands of customers who want green practices.

- Recycled paper and eco-friendly inks are becoming standard.

- Energy-efficient equipment helps reduce energy use.

- Certifications like FSC demonstrate environmental commitment.

- Businesses are focusing on minimizing waste and optimizing resources.

Automation and Workflow Optimization

Automation is crucial for improving productivity and efficiency within the print industry. Automation of workflows is helping businesses decrease manual intervention, minimize mistakes, and streamline production processes. Technologies, such as automated pre-press operations, robotic handling systems, and automated finishing equipment, are becoming more common. These solutions help accelerate production speeds, decrease expenses, and enhance quality control. As automation improves, print businesses can handle increased demand and stay competitive by optimizing their operations.

- Automated pre-press operations improve workflows and reduce manual errors.

- Robotic handling systems enhance speed and accuracy in production.

- Automated finishing equipment simplifies the post-print steps.

- Automation results in improved output, reduced expenses, and enhanced quality control.

Advanced Printing Technologies

The print industry is continuously developing, and new technologies are appearing, enhancing the possibilities and capabilities of print. Advanced technologies like inkjet printing, 3D printing, and other specialized techniques are pushing boundaries and providing innovative solutions. Inkjet technology provides excellent quality, speed, and versatility, making it perfect for a range of applications, from commercial printing to packaging. 3D printing is growing in fields such as prototyping and the creation of customized products. The integration of these innovative technologies demonstrates the ability of the print industry to adapt and provide advanced solutions.

Inkjet Printing and Its Applications

Inkjet printing has become a vital technology in the print industry, known for its versatility, speed, and great print quality. Inkjet printers employ tiny nozzles to spray ink onto a surface, creating images and text with extreme accuracy. This technology is used in numerous applications, from home and office printing to commercial production. Advantages of inkjet printing include the ability to print on diverse materials, such as paper, plastic, and textiles, and the support of variable data printing. As technology advances, inkjet systems are improving in speed, resolution, and ink formulations, expanding their capabilities and applications across the industry.

- Inkjet technology offers high-resolution output and sharp images.

- It can print on a variety of substrates, offering greater flexibility.

- Variable data printing is simple, allowing for custom prints.

- Continued innovations enhance speed, resolution, and ink options.

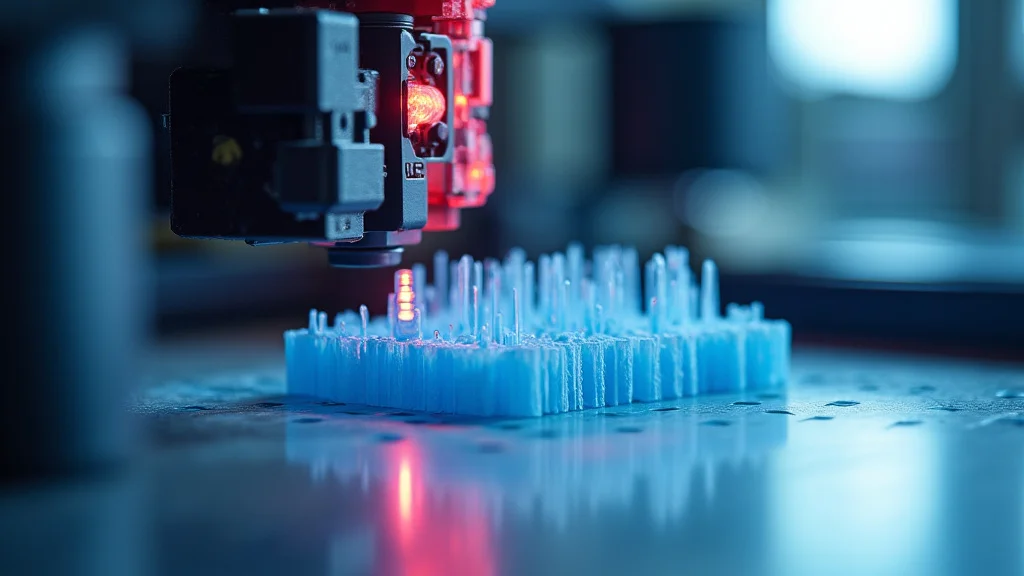

3D Printing: A New Frontier

3D printing, also known as additive manufacturing, has revolutionized prototyping and production in diverse sectors. It involves building three-dimensional objects layer by layer from a digital design. In printing, 3D printing offers businesses the ability to create customized products, prototypes, and specialized components with great speed and efficiency. The technology provides designers and manufacturers with new possibilities for design flexibility, reduced material waste, and rapid prototyping. 3D printing is being used for packaging, personalized gifts, and specialized industrial components. As this technology develops, it is set to change how things are designed and manufactured.

- 3D printing builds objects layer by layer from digital designs.

- It allows for the creation of prototypes and custom components.

- This technology helps reduce material waste and speeds up the prototyping process.

- 3D printing is being used in packaging and producing specialized industrial parts.

Specialized Printing Techniques

Specialized printing methods offer customized solutions and are designed for specific applications, enhancing the versatility of the print industry. These techniques encompass a variety of methods, like screen printing, flexography, and gravure printing, each suited for particular requirements and output requirements. Screen printing is great for printing on textiles, while flexography is used for packaging and labeling. Gravure printing is perfect for high-volume jobs, like magazines and catalogs. By using specialized techniques, businesses can meet the increasing need for custom outputs, improved quality, and effectiveness in niche markets, ensuring that they can satisfy their customers’ individual needs.

- Screen printing is perfect for printing on materials like fabrics.

- Flexography is widely used for labels and packaging.

- Gravure printing is used for high-volume printing jobs.

- These techniques allow for improved quality and custom solutions.

The Impact of Digital Technologies

Digital technologies have significantly changed the print industry, transforming how businesses operate and how services are provided. The shift towards digital printing, cloud-based workflows, and automated production processes is boosting efficiency, reducing costs, and enabling greater customization. Online platforms, web-to-print solutions, and data analytics tools have also changed how print businesses interact with their customers, manage their projects, and optimize their processes. These technologies have revolutionized the print sector, empowering businesses to be more competitive, flexible, and customer-centric in a rapidly changing market.

Web-to-Print Solutions and E-commerce Integration

Web-to-print platforms and e-commerce integration have transformed how print businesses manage orders and interact with customers. These solutions allow customers to upload files, personalize designs, and request prints online, simplifying the ordering process. Web-to-print solutions automate quote creation, order processing, and production workflows, saving time and decreasing mistakes. The integration of e-commerce platforms enables print businesses to widen their reach, provide services 24/7, and better meet customer needs. This integration helps businesses become more competitive, improve efficiency, and enhance customer satisfaction in a digitally driven market.

- Web-to-print systems allow customers to order prints online with ease.

- Automated processes save time and reduce errors.

- E-commerce integration expands market reach and improves customer service.

- These solutions boost competitiveness and customer satisfaction.

Data Analytics and Personalized Printing

Data analytics and personalized printing are changing how businesses approach their projects, leading to more customized and impactful outputs. Data analytics tools help print businesses gather and interpret data on customer preferences, market trends, and print performance. This information can be used to improve workflows, target marketing efforts, and create personalized print materials. Personalized printing, which includes variable data printing, helps companies tailor print materials for individual customers, enhancing engagement and response rates. By using data analytics and personalization, print businesses can produce more relevant, effective, and customer-centric outputs, improving customer engagement and campaign results.

- Data analytics offers insights into customer behavior and market patterns.

- Personalized printing improves the relevance and impact of print materials.

- Variable data printing is used to create personalized materials for customers.

- Businesses can improve engagement and campaign results through personalization.

Cloud Computing and Workflow Automation

Cloud computing and workflow automation are key for improving efficiency and collaboration in the print sector. Cloud-based solutions allow print businesses to store, access, and manage data from anywhere, improving collaboration and increasing flexibility. Workflow automation streamlines processes like file preparation, job management, and production tracking, reducing manual work and errors. Automation tools can be integrated with cloud systems, improving efficiency and visibility across the entire workflow. By adopting cloud computing and automation, print businesses can optimize their processes, improve productivity, and stay competitive in a fast-paced market.

- Cloud solutions improve data access and collaboration.

- Workflow automation streamlines processes and reduces manual effort.

- Automation tools work together with cloud systems to improve efficiency.

- Businesses can improve productivity and maintain a competitive edge.

Sustainable Practices in Printing

Sustainability is no longer an option, but a necessary aspect in the printing industry. Consumers are increasingly demanding environmentally friendly products, leading businesses to adopt sustainable practices. From using eco-friendly materials and energy-efficient equipment to minimizing waste and participating in recycling programs, the industry is constantly changing. By adopting sustainability, print businesses can reduce their environmental impact, enhance their reputation, and meet customer needs. This commitment to sustainability is crucial for the long-term success of the print sector.

Eco-Friendly Materials and Inks

Using eco-friendly materials and inks is central to sustainable printing. Businesses are using recycled paper, plant-based inks, and other sustainable materials to decrease their impact on the environment. Recycled paper reduces the requirement for new resources, while plant-based inks are made with sustainable materials and emit fewer volatile organic compounds (VOCs). By choosing environmentally friendly materials, print businesses can create high-quality products, while reducing their carbon footprint. This commitment to sustainable materials meets consumer demand and promotes the health of the environment.

- Recycled paper reduces the requirement for virgin materials.

- Plant-based inks reduce VOC emissions and use sustainable sources.

- The use of eco-friendly materials enhances environmental performance.

- Businesses can satisfy customer demand and reduce their carbon footprint.

Energy-Efficient Equipment and Processes

Improving energy efficiency is an important part of sustainable printing. Businesses are using energy-efficient equipment, such as LED lighting and high-efficiency printers, to reduce energy consumption and operational costs. Adopting energy-efficient methods, like optimizing print runs and reducing waste, can also contribute to lower energy use. Energy audits can help businesses determine areas for improvement and implement efficiency-driven strategies. By focusing on energy efficiency, print businesses can decrease their environmental impact, reduce costs, and improve their long-term sustainability.

- Using LED lighting and high-efficiency printers minimizes energy consumption.

- Optimizing print runs and reducing waste improve energy efficiency.

- Energy audits help identify opportunities for improvement.

- Energy efficiency leads to lower environmental impact and reduced expenses.

Waste Reduction and Recycling Initiatives

Waste reduction and recycling are crucial for sustainable printing. Print businesses are adopting waste management practices to minimize waste and promote recycling of materials like paper, ink cartridges, and printing plates. Optimizing print processes, implementing paper-saving methods, and streamlining workflows can minimize waste generation. Participating in recycling programs and partnering with recycling companies helps ensure that materials are effectively recycled. Waste reduction and recycling contribute to a circular economy, saving resources, and reducing the environmental impact of printing operations. This initiative is crucial for sustainability.

- Waste management practices minimize waste production.

- Paper-saving methods and streamlined workflows optimize print processes.

- Participation in recycling programs ensures materials are effectively recycled.

- Waste reduction supports a circular economy and reduces environmental impact.

Challenges and Opportunities in the Industry

The print industry faces several challenges, but also offers many opportunities for growth and innovation. Economic volatility, competition from digital media, and environmental regulations pose important hurdles for print businesses. However, developments in technology, the growing demand for customized print solutions, and the increasing importance of sustainability provide significant opportunities for growth. To succeed, businesses need to be able to adjust to change, embrace innovation, and improve their customer relationships. The print sector can stay at the forefront and continue to provide value in the future by addressing these challenges and utilizing these opportunities.

Economic Factors and Market Fluctuations

Economic factors and market changes significantly affect the print sector, influencing the demand for print services, costs, and investment choices. Changes in the economy, like recessions or inflation, affect customer spending and influence advertising budgets, that can decrease print demands. Print businesses must understand economic trends, adapt their business models, and manage costs to maintain stability. Diversifying services, growing digital offerings, and focusing on customer service can help businesses weather economic volatility and maintain their competitiveness. Staying flexible and responsive to market fluctuations is crucial for success.

- Economic recessions can reduce demand for print services.

- Inflation can affect the cost of materials and operations.

- Diversifying services and expanding digital offerings enhances resilience.

- Flexibility and responsiveness are key to weathering market changes.

Competition from Digital Media

Competition from digital media is a key challenge for the print sector. The rise of digital advertising, social media, and online content delivery has diverted budgets from traditional print media. Print businesses must differentiate their services by delivering high-quality, customized products, and emphasizing the advantages of print, such as tangibility, durability, and brand impact. Incorporating digital technologies, like augmented reality and QR codes, to enhance print materials can create interactive experiences that complement digital channels. Focusing on value-added services and embracing new technologies can help print businesses stay competitive in the digital age.

- The rise of digital advertising has decreased demand for print.

- Differentiation through high-quality products is key.

- The use of interactive features enhances the customer experience.

- Focusing on value-added services increases competitiveness.

Technological Advancements and Innovation

Technological advancements and innovation create both challenges and opportunities for the print industry. Businesses must stay updated with the newest technologies and embrace new tools to stay competitive. Investment in digital printing systems, automation solutions, and software is essential for enhancing efficiency, quality, and customization. Additionally, innovation in areas like sustainable materials, 3D printing, and personalized print is generating new growth possibilities. To succeed, businesses need to invest in research and development, train their employees, and be willing to innovate and adjust.

- Businesses must invest in digital printing systems.

- Automation solutions enhance efficiency and quality.

- Investment in R&D is crucial for staying ahead.

- Innovation creates opportunities for growth.

Common Myths Debunked

Myth 1: Printing is a Dying Industry

Reality: While the print industry has changed due to digital media, it’s not disappearing. It continues to be important in marketing, packaging, and custom projects. The industry is adjusting by using new technologies, like digital printing and sustainable practices, to meet customer demands.

Myth 2: Digital Printing is Always More Expensive

Reality: Digital printing can be more cost-effective for short print runs and personalized projects. Although the initial cost of digital printing can be greater than other traditional printing methods, it eliminates the costs of plate creation, and setup, making it ideal for smaller volumes. The cost efficiency depends on print requirements.

Myth 3: All Print Shops are the Same

Reality: Print shops vary greatly in their services, equipment, and specialization. Some specialize in commercial printing, while others concentrate on packaging, or large-format printing. Businesses must carefully pick a print shop that can meet their particular needs.

Myth 4: Printing is Bad for the Environment

Reality: Although traditional printing can harm the environment, the industry is increasingly embracing sustainable practices. Businesses are adopting eco-friendly materials, minimizing waste, and decreasing their carbon footprint. Sustainable printing is becoming more common, decreasing its impact on the planet.

Myth 5: You Can’t Get High-Quality Prints from Digital Methods

Reality: Digital printing technology has improved substantially, offering print quality comparable to other traditional print techniques. Modern digital printers offer high resolution, vivid colors, and accurate outputs, making them suitable for professional uses like marketing materials, books, and photographs.

Frequently Asked Questions

Question: What is the main trend in printing?

Answer: The integration of digital technologies and focus on sustainable practices are main trends.

Question: What is the future of the print industry?

Answer: The industry will likely continue to integrate digital technologies.

Question: What is digital printing?

Answer: A print technique that uses digital files to create prints directly.

Question: What is 3D printing used for?

Answer: It is used for prototyping, creating custom products, and creating specialized parts.

Question: What are eco-friendly practices in printing?

Answer: They include the use of recycled paper, eco-friendly inks, and energy-efficient equipment.

Final Thoughts

As we’ve explored the landscape, it’s clear that the future of the print industry is dynamic and filled with change. From the historical context to the innovative technologies that are emerging, printing united 2025 is set to be a transformative era. The convergence of digital technologies, sustainability efforts, and automation offers exciting possibilities for businesses and consumers. By embracing these changes, businesses can improve their operations, stay competitive, and deliver value to their clients. Whether you’re a business owner or a printing enthusiast, the information you’ve gained will give you a better grasp of the print industry and its ongoing evolution. Keep up with the latest advancements, understand the changing market dynamics, and focus on sustainable practices. The future is bright for those who embrace change and innovation!